8 Simple Steps to Specifying a Transformer

We at Wilson Power Solutions promote product innovation, engineering excellence and a strong sense of social and environmental responsibility.

Our 70 years of experience in the industry can’t be ignored, as we endeavour to help our customers find the best power distribution solution for their needs.

This simple guide highlights how our expertise can help your business or organisation save energy and money.

Why has energy sustainability become more important?

All of a sudden, businesses are being forced to recognise and take responsibility for their energy activities. However, it’s not only businesses, as we as individuals, societies and a planet are too having to adjust.

The World Energy Council are championing energy sustainability and basing it on three core dimensions: energy security, energy equity, and environmental sustainability. These ambitious goals are being referred to as a ‘trilemma’, for many different sectors and organisations, as they look to combat, adapt and deliver an energy transformation towards a more sustainable future.

Where can you look to save energy?

Due to new legislation being enforced, as a planet, we are rapidly looking for additional energy saving solutions. More often than not, we look to the obvious ideas such as monitoring lighting and heating in your work environment or at home, however, the time has come to look ‘beyond the low hanging fruit’ and upgrade your energy supply infrastructure.

Your power supply transformer, or distribution transformer, can often be outdated and therefore a direct result of mass energy wastage. Replacing or upgrading your existing transformer can prove to be an intelligent move, as over 750 of our customers have already discovered.

How important is your transformer specification?

Ensuring your transformer is firing on all cylinders and evading any issues, is crucial to any operation. If there are issues, we can often trace it back to inaccurate transformer specification. So, we look to provide our customers with accurate specifications and solutions, to prevent any unnecessary wastage or problems.

To make this digestible we have introduced a ‘4P’ process.

Programme

Reduce the likelihood of any changes to the programme which can cause delays.

Problems

Eliminate likelihood of misunderstandings regarding deliverables and key milestones.

Product

Provide a product that is fit for purpose and suitable for the application.

Price

Provide a more cost effective solution.

This process ensures that your programme is on track, that you will receive your equipment when you need it, with all required testing carried out, complete with all documentation, fit for purpose and at the right price.

All the above will help save on initial investment cost and the lifetime cost of the transformer.

Why have transformer specifications become more important?

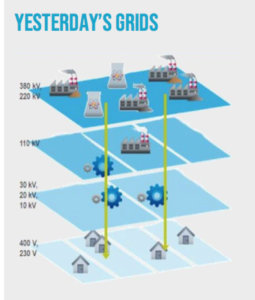

Traditionally, power flows from generation to load (high voltage to low voltage) and our entire grid infrastructure was built for this unidirectional flow.

Historically, the load on the network was very predictable, as can be seen in the graph below. Peaks and troughs could be easily forecast, with a distinction between summer and winter months.

As a result transformer designs and standards have been tailored to accommodate such loading profiles. It is also worth mentioning that the supply was very clean due to both generation and load being more analogue (generation from combustion fuels) and no power electronics (load).

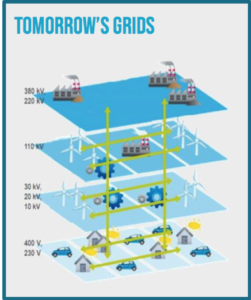

We are now seeing generation and loads being introduced at several stages along the network, and flows can be bi-directional and introduce or increase unwanted phenomena.

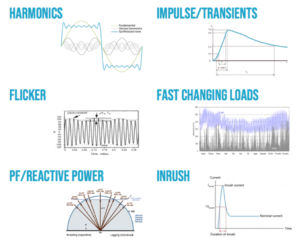

Tomorrow’s grid will be very different from the one we have today. The introduction of unpredictable generation and what are known as ‘dirty loads’ will change how the network operates. Some of the main phenomenons that can occur include the following:

If you recognise any of the above, and have been affected by them before, you can now begin to understand why transformer specifications have become more important.

Your 8 simple steps to writing a transformer specification

-

Step 1 – What Specification Standards Apply?

It’s crucial to know your specification standards and which is most appropriate for your project. It’s not unusual for some standards to be tailored towards particular applications, referencing several specifications which could contradict one another, so get to know your content.

-

Step 2 – Transformer Application

There are multiple types of transformer, so it’s important to specify the application of the transformer, beforehand. Just like how a car evolves through application and technology, it has not necessarily changed fundamentally, similar to transformers. So making sure you select the right model (or design) to suit your project and environment is essential.

-

Step 3 – Voltage & Regulation

Although this seems straightforward it’s still worth being cautious about. In fact, confusion over load and no load voltages is the most common error that we encounter in specifications from customers. In short: understand the possible variation of the system and ask yourself how often will the voltage change and how fast a response is required.

-

Step 4 – Vector Grouping

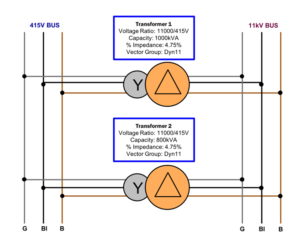

Understand your vector groups and what they mean. There are a series of letters relating to the high voltage winding and are denoted by a capital letter. Writing your vector group will take a level of understanding but, as the diagram shows, these two transformers are to be connected together in parallel, as a result they have to have the same vector rotation. Therefore, vector grouping is a key component to the success.

-

Step 5 – Impedance

An ideal transformer is made up of two parts, a resistive and inductive (reactive) part, the combination of the two together is what we class as the impedance.

Impedance is the most important characteristic in a transformer; any alteration will have an effect on most aspects of a transformer design and, as a result, if the impedance is altered, the transformer design will need a complete overhaul. Ensure you always match parallel impedances and get your impedances verified!

-

Step 6 – Losses

As stated earlier, an ideal transformer only has two parts, but unfortunately the ideal transformer doesn’t exist because losses do occur. In transformers, there are three types of losses:

Load losses (also known as Copper losses) – these are generated by current flowing through the windings and the loss of power due to the resistance of the material. These losses are only present when there is a load on the circuit.

Leakage flux losses – these are generated by an electrical field which cause stray losses in the tank and other metallic parts.

No load losses (also known as core or iron losses) – these are generated by the core of the transformer due to eddy currents in the core and Hysteresis losses. These are present when the transformer is operating in both open (under volts but no load) and closed circuits.

The energy wasted through transformer losses in the UK, could power Denmark for three years. Our payback calculations can reveal substantial savings over the lifetime of your transformer.

It is also worth knowing that all standard transformers have to comply with the Eco Design Directive, and our Wilson e3 (featuring innovative amorphous technology) already exceeds 2021 loss requirements.

-

Step 7 – Environmental Considerations

Environmental consideration can have a large impact on the design of a transformer. There are several parameters to consider and the most common ones are: noise levels, fire hazard, contamination risks and climatic conditions on site.

Transformers are required to be compliant, especially with the rise of the renewable markets. Currently, we have varying methods and solutions to help combat most environmental implications, but make sure all environmental considerations have been accounted for so that the transformer is fit to perform its task.

-

Step 8 – Monitoring & Protection

Here, in order of current popularity, are three monitoring and protection options:

Smart Equipment

A relatively new addition allowing the user to look at all aspects of the transformer, to better understand how ‘healthy’ the transformer is.

Continuous Monitoring

These are used to monitor the transformer and allow the user to detect a fault before it gets to a critical stage.

Reactive Protection

Typically, these pieces of equipment are designed to react to a fault, to save the transformer.

Assessing the ongoing performance of your transformer, and identify issues before they occur, will result in a transformer with lower losses, saving you both energy and money.

CPD Seminars with Wilson Power Solutions

If you can specify exactly what it is you need you can get the transformer that is ideal for your application, but get it wrong and you could be spending money where it isn’t needed. A bad transformer specification can lead to decades of wasted energy.

For a more in depth analysis, and tutoring on how to draw up your transformer specification, you can register for our CPD seminars online. Register today, to help you and your business evolve your understanding on energy infrastructure and make sustainable energy systems a reality.

21 Jan 2019

21 Jan 2019IETF: Industrial Energy Transformation Fund – Phase 3

Industrial emissions account for around 18% of UK emissions. To reach the Net Zero target in 2050, industrial emissions need to fall by around 90% from today’s levels. Industrial Energy Transformation Fund (IETF) launched Phase 3 of industrial grants on Monday 29 January 2024, with the closing date on Friday 19 April 2024, and aims […]

23 Feb 2024

23 Feb 2024Guide to Replacing Transformers

The third part of the Intergovernmental Panel on Climate Change (IPCC) Sixth Assessment Report (AR6) was published earlier this month. Scientists warn that limiting global warming to 1.5°C is beyond reach but restricting temperature rise to no more than 1.5C to 2C could be the range that will minimize the likelihood of reaching critical environmental […]

22 Apr 2022

22 Apr 2022IETF: Industrial Energy Transformation Fund FAQ

The Industrial Energy Transformation Fund (IETF) was designed by the UK government to encourage energy-intensive businesses to cut their carbon emissions and reduce their energy waste by switching to energy-efficient low-carbon technologies. A budget of £315 million was allocated by the government to be spent through the IETF. BEIS manages England, Wales and North Ireland’s […]

4 Apr 2022

4 Apr 2022