University of East Anglia – Super Low-Loss Transformers

Background

University of East Anglia [UEA] is one of the UK’s top 15 Universities and part of the top 300 Universities globally. It is a campus University of about 300 hectares and 90 buildings and on a “normal” day frequented by around 20,000 humans and about 5,700 other species, according to a recent biodiversity study.

Being a centre of excellence in environmental sciences and climate research, UEA launched a comprehensive energy and carbon reduction programme (ECRP) in 2015. Sustainable development at UEA means that the University is trying to balance the ‘three pillars’ of environmental, economic and social elements of sustainability.

UEA achieve this by challenging their environmental impact through reducing their reliance on grid electricity and therefore fossil fuels, as well as promoting recycling and ‘eco’ products such as biological cleaning materials. UEA champions local suppliers and ethical causes and, importantly in the context of capital programmes, seeks to ensure value for money in a holistic, whole-life costing sense.

Given its very diverse building stock this is no mean feat. Having some of the highest performing buildings in the UK such as The Enterprise Centre (built in 2015 to Passivhaus standards) alongside poorly performing buildings including original 1960’s science and other faculty buildings and residences like the Ziggurats.

Infrastructure includes 5.7 MWe of gas CHP generating 70% of heat and power as well as cooling via tri-generation with extensive district heating and cooling and a wholly owned 11kV network with 22 substations and 26 supply transformers.

Design Guide

To achieve best practice and help avoid blinkered “value engineering” approaches that all too often lead to higher operating costs in the long run, the University has developed a “Design Guide” that serves as a procurement and specification guide across its estate. The guide helps the university to control the quality of operations by ensuring design best practice and procurement compliancy with the university’s strategic development.

The guide is structured into specific sections /disciplines or area of design responsibility and is available for free on the university’s website on https://portal.uea.ac.uk/estates/building-design-guide.

Energy Savings Beyond the Low Hanging Fruit

Amorphous Transformers- New Build

UEA’s total utilities cost is over £3.6 million per year, £900k of that are electricity. When energy managers think of energy efficiency and reduced losses, they tend to focus on inside-the-building solutions. Transformers are often neglected as they have a relatively long lifetime (average of 63 years in the UK).

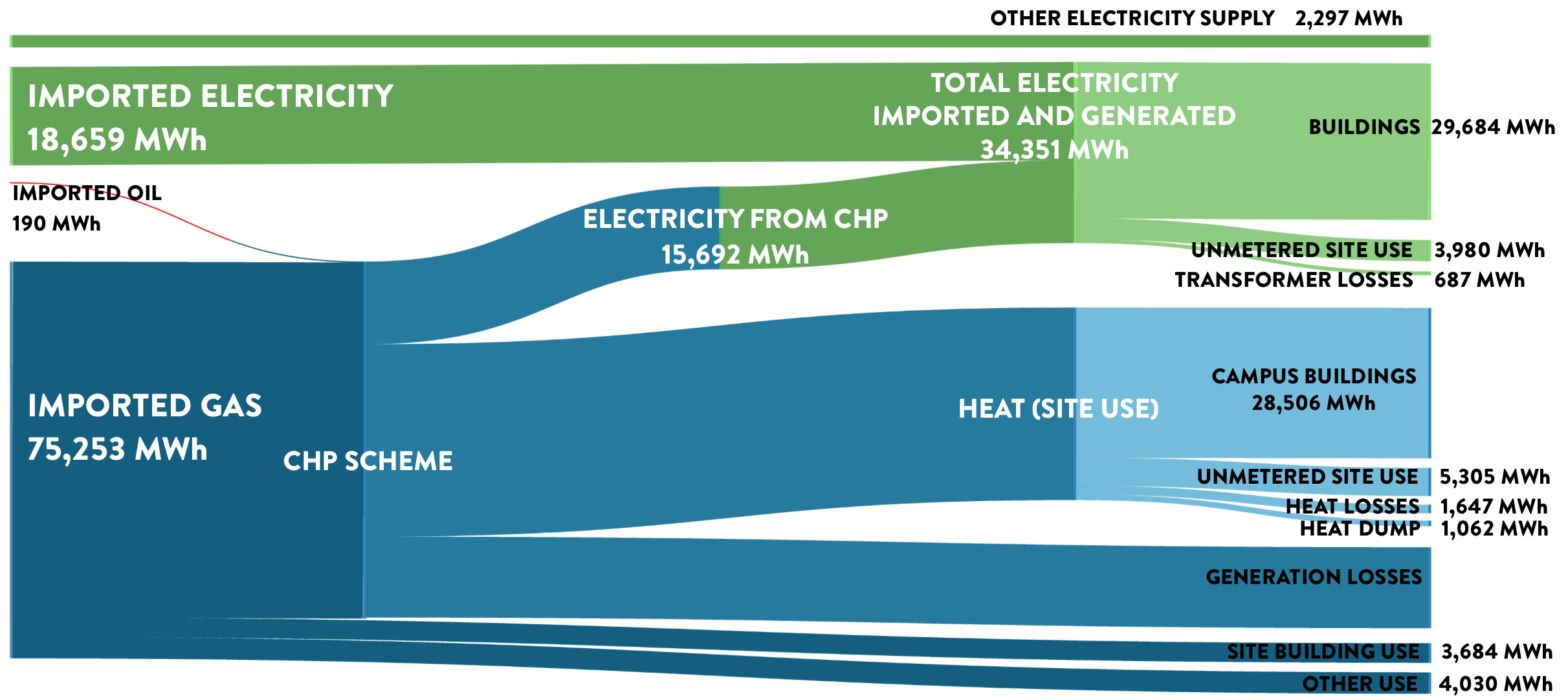

However, almost 2% (678 MWh) of the total imported and generated electricity is wasted due to transformer losses (see diagram) across the University Estate’s 22 substations. That is equivalent to over £74k (based on electricity costs of £0.11/kWh). Despite this being a challenge, it comes with a lucrative opportunity for the university to save energy, money and reduce its carbon emissions if the right technology gets installed in place.

University of East Anglia University – Utilities Sankey Diagram

With transformer losses on the radar of the University’s engineering, utilities and maintenance teams, UEA’s Design Guide specified “super low loss amorphous transformers” since 2016 to help address this unnecessary energy wastage. Part 6 of UEA’s Design Guide deals with electrical systems and can be found here: https://portal.uea.ac.uk/estates/building-design-guide/part-6. It discusses electrical systems including private HV & LV systems, load assessment, voltage optimisation, power factor correction and others.

Super low loss amorphous transformers (such as the Wilson e2) already exceed strict new EU Eco Design requirements (Tier2) due to come into force in 2021 thus providing significant whole lifecycle savings.

Super low-loss is achieved as a result of using amorphous as a core material that has less hysteresis losses than the cores of conventional transformers. This reduces the energy wasted as heat during the magnetisation and demagnetisation processes and reduces energy losses in distribution transformers by almost half.

Conventional distribution transformers use Cold Rolled Silicon Steel (CRGO) which consists of stacks of laminations that are made from silicon steel with an almost uniform crystalline structure. Whereas amorphous metal is made of alloys that have no atomic order. They are made by rapid cooling of molten metals that prevents crystallisation and leaves a vitrified structure in the form of thin strips.

This means that new build projects such as the Barton & Hickling residences and currently under construction “Building 60”, a new 6000sqm combined science teaching building are powered by highly efficient supply transformers that cost more upfront (higher capital cost) but achieve significant lifetime energy efficiency savings (better operational costs).

With typical lifetime savings of over £50,000 for a single 1MVA transformer, this infrastructure decision will save the University hundreds of thousands of pounds to re-invest into its estate over years to come.

Room for Improvement- Transformer Replacement

One area of energy efficiency improvements that UEA hasn’t benefited from thus far is the replacement of aged supply transformers. Inspired by a recent transformer replacement viability study at a large hospital near Dundee that will save the trust over £7,300 pa in electricity costs on one transformer replacement alone, the University is planning to carry out its own load profiling and power quality analysis project with a view to highlight similar opportunities in its 22 substations on site.

First candidates from an admittedly low-key exterior inspection: A 1961 South Wales Switchgear 750kVA unit in the Sciences HV Substation and a 1960 South Wales Switchgear 1000kVA unit at Waveney. This is a picture of 1000kVA South Wales Switchgear Transformer from 1960.

Published on: Energy Manager Magazine

13 Jun 2019

13 Jun 2019IETF: Industrial Energy Transformation Fund – Phase 3

Industrial emissions account for around 18% of UK emissions. To reach the Net Zero target in 2050, industrial emissions need to fall by around 90% from today’s levels. Industrial Energy Transformation Fund (IETF) launched Phase 3 of industrial grants on Monday 29 January 2024, with the closing date on Friday 19 April 2024, and aims […]

23 Feb 2024

23 Feb 2024Guide to Replacing Transformers

The third part of the Intergovernmental Panel on Climate Change (IPCC) Sixth Assessment Report (AR6) was published earlier this month. Scientists warn that limiting global warming to 1.5°C is beyond reach but restricting temperature rise to no more than 1.5C to 2C could be the range that will minimize the likelihood of reaching critical environmental […]

22 Apr 2022

22 Apr 2022IETF: Industrial Energy Transformation Fund FAQ

The Industrial Energy Transformation Fund (IETF) was designed by the UK government to encourage energy-intensive businesses to cut their carbon emissions and reduce their energy waste by switching to energy-efficient low-carbon technologies. A budget of £315 million was allocated by the government to be spent through the IETF. BEIS manages England, Wales and North Ireland’s […]

4 Apr 2022

4 Apr 2022